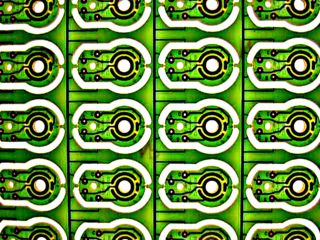

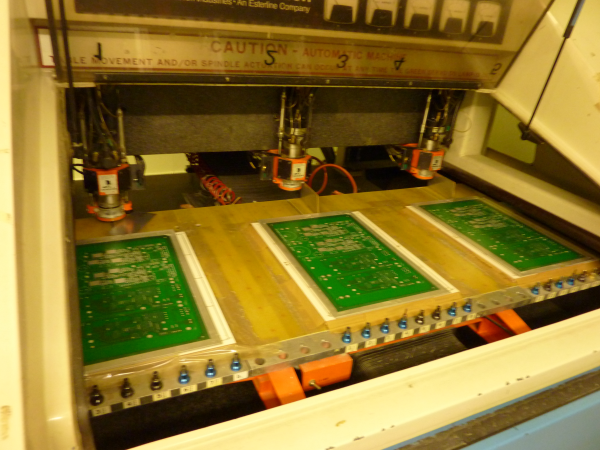

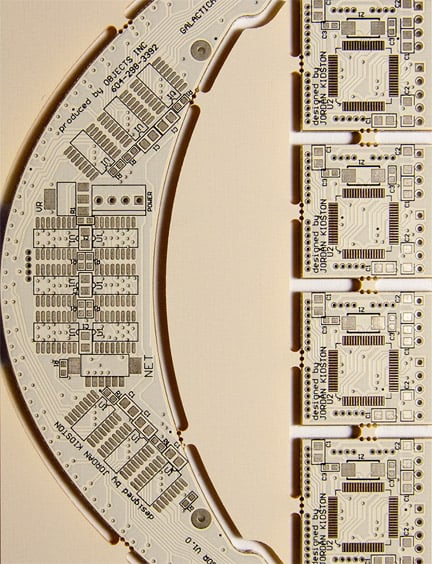

One of the more interesting activities routinely associated with PCB manufacturing is the process of assembling multilayer circuit boards.

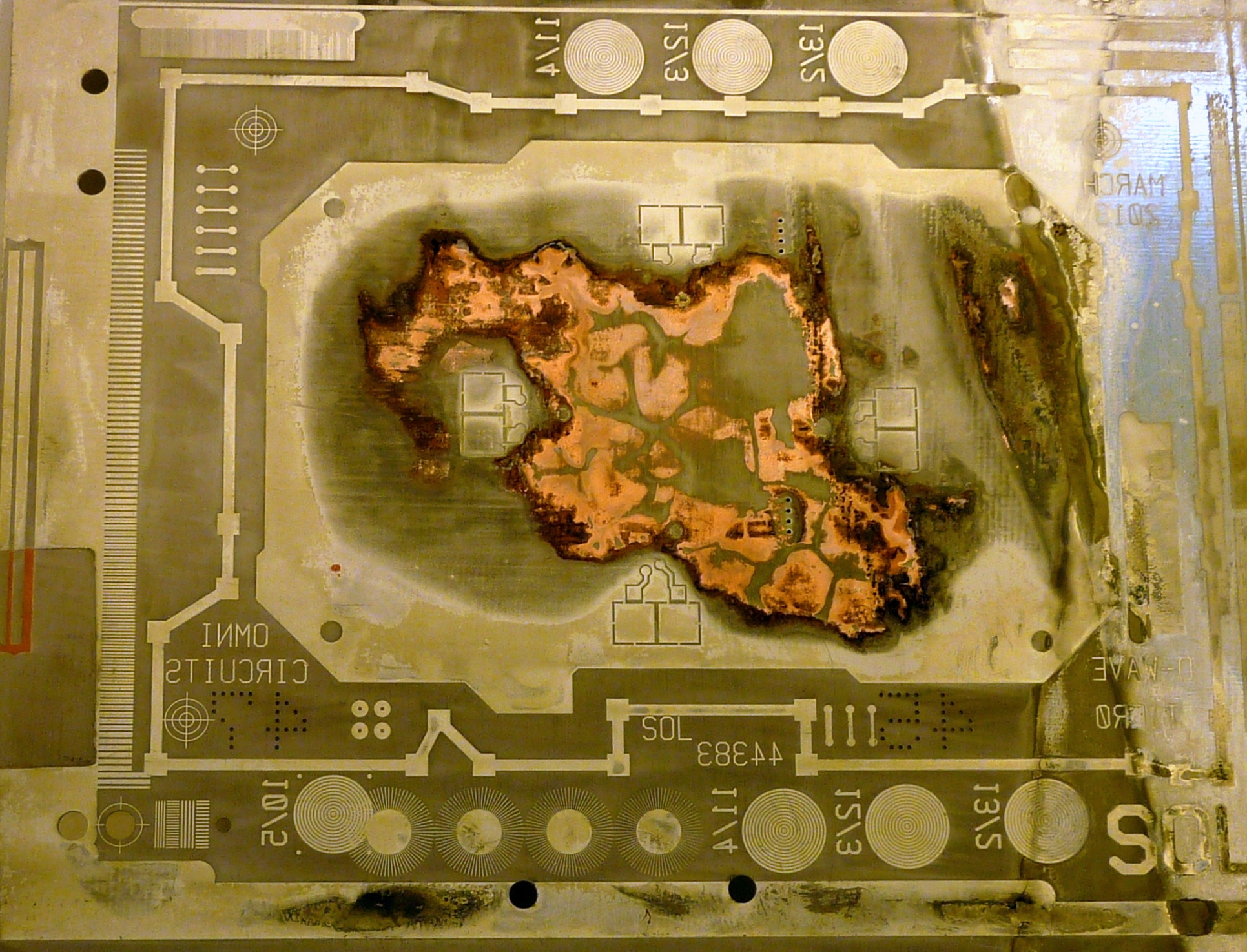

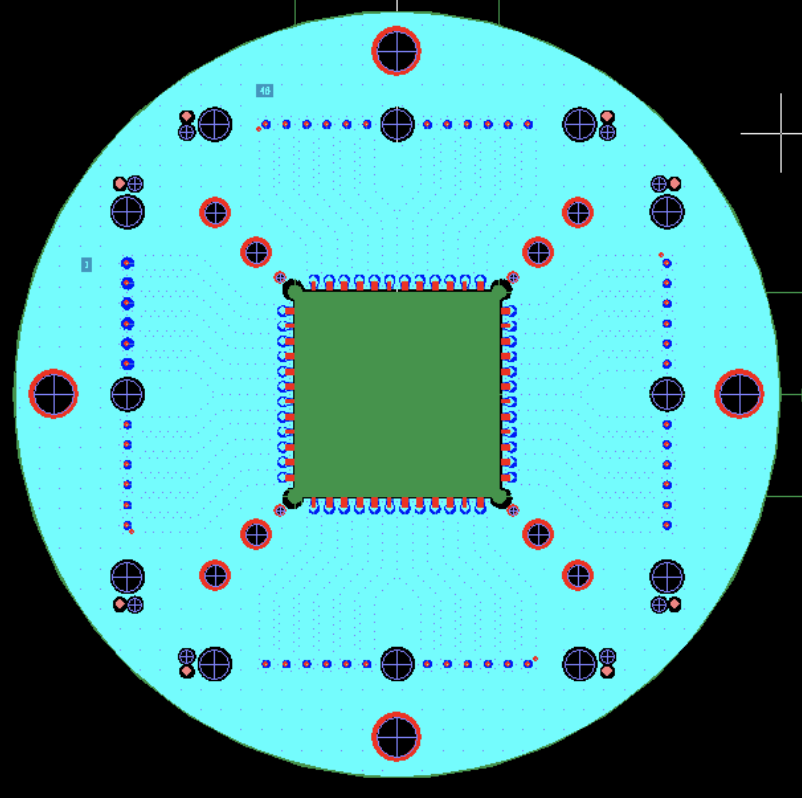

At any given time 60% of our PCB manufacturing at Omni is producing multilayer circuit boards, so understanding the process is important. Layers of copper foil, pre-preg and core material are sandwiched together under high temperature and pressure to produce multilayer assemblies. Pressure is needed to squeeze out air while heat is required to melt and cure the thermosetting “pre-preg” adhesive which holds the multilayer PCB together.

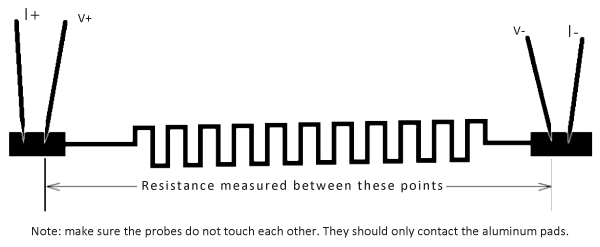

%20microwave%20laminate.png)