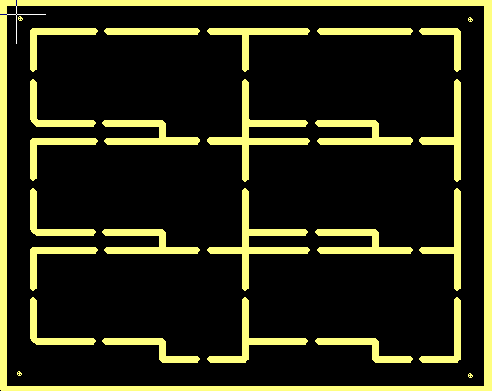

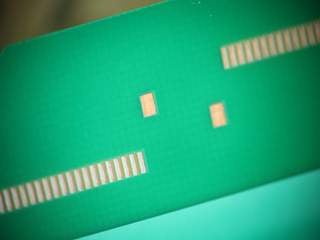

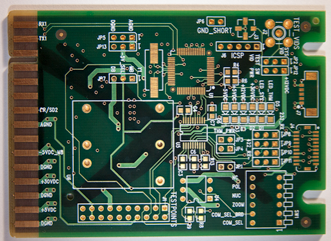

The purpose of panelization is to secure PCB boards during manufacturing, shipping and assembly processes and faster throughput while making their separation as painless as possible.

PCB Manufacturer = The company that manufactures blank PCBs for you, Omni Circuit Boards Ltd is a "PCB Manufacturer"

PCBA Manufacturer = The company that manufactures an assembled or populated PCB for you, also known as CMs or contract manufacturers.