The problem when soldering to Aluminum

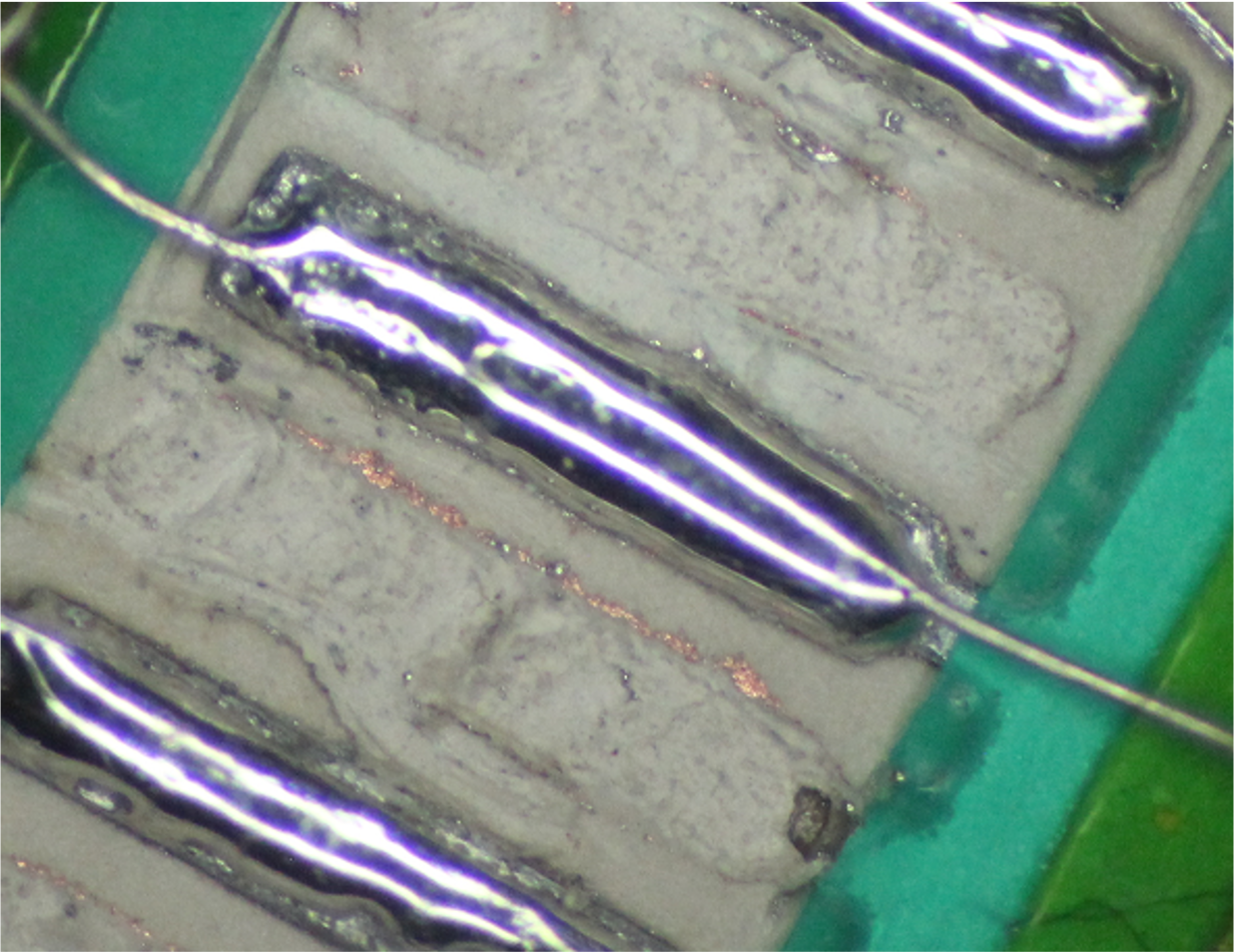

Aluminum reacts very quickly with oxidizers in the air. It immediately develops a passive layer of aluminum oxide surrounding the pure metal, making it difficult to solder than copper.

Aluminum reacts very quickly with oxidizers in the air. It immediately develops a passive layer of aluminum oxide surrounding the pure metal, making it difficult to solder than copper.

Fri, May 12, 2023 @ 02:51 PM Natalia Piedras Aluminum Trace PCB - Superconductive PCB

Read More »

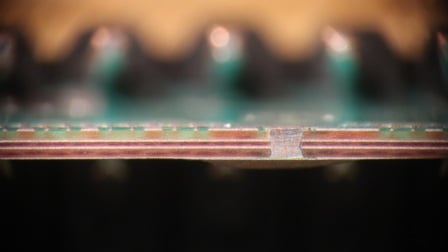

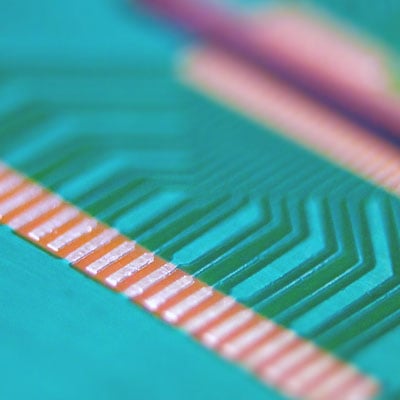

A circuit trace is a conducting track on a printed circuit board that connects components electrically and allows electric current to flow with little resistance.

While this small resistance is inconsequential for most applications, there are applications where the heat dissipated due to this small resistance is a big problem.

Much like how normal conducting trace allows current to flow, they also allow heat to flow from higher temperature areas to areas of lower temperature.

Mon, Jul 27, 2020 @ 01:11 PM Natalia Piedras Printed Circuit Board Design, Aluminum Trace PCB - Superconductive PCB

Read More »

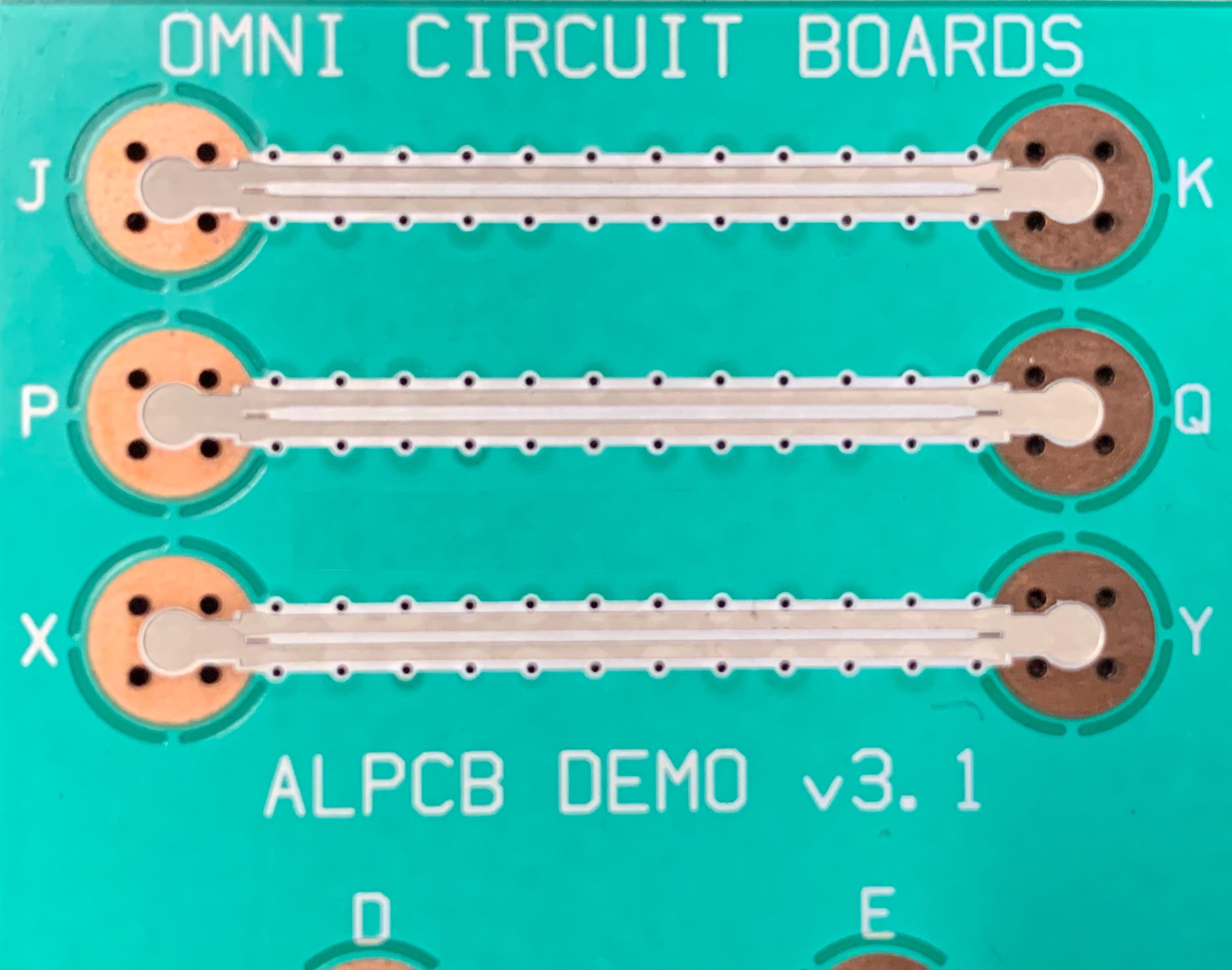

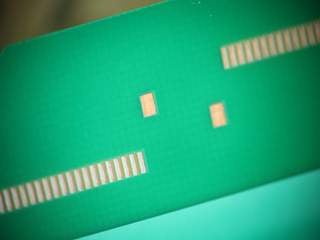

Beginning in 2008, Omni Circuit boards was challenged by a strategic partner with developing a circuit board with fine-line aluminum traces. The reason for aluminum in the initial quest was for its superconducting (cryogenic) properties. But as time went by, we began to appreciate how developing this capability could also benefit customers who have a requirement for aluminum wire bonding of critical components and non-magnetic properties.

Wed, Jan 22, 2020 @ 04:35 PM Omni Team Aluminum Trace PCB - Superconductive PCB

Read More »

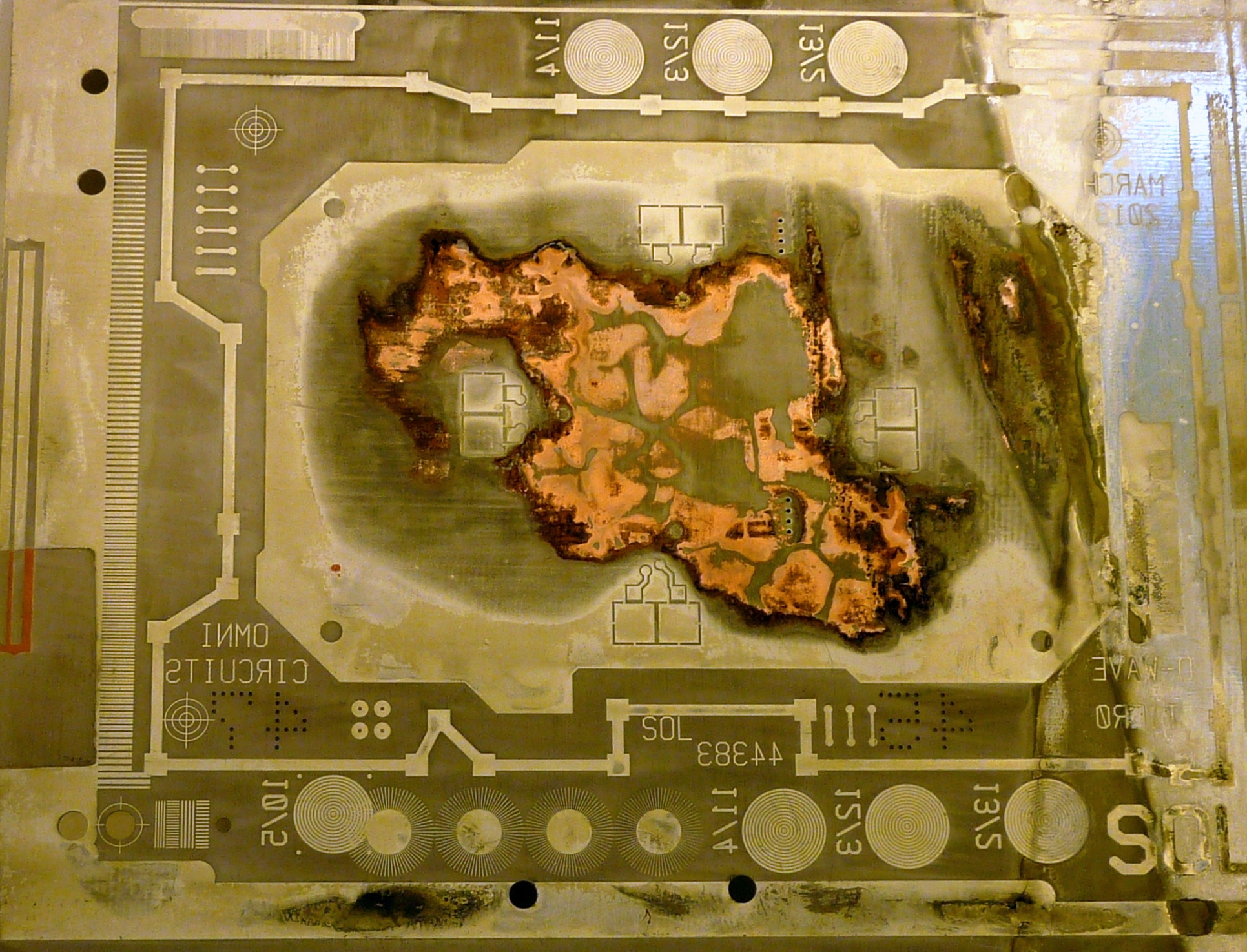

That's why it was no surprise when the engineers at British Columbia based D-Wave Systems came to us looking for a unique product.

Tue, Aug 27, 2019 @ 02:03 PM Omni Team Aluminum Trace PCB - Superconductive PCB

Read More »

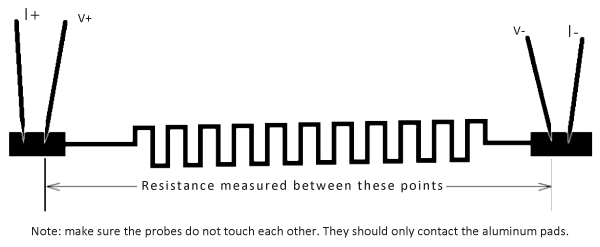

Measuring resistance of a fine-line Aluminum Trace provides different challenges compared to traces on a Copper PCB, most importantly, the surface aluminum oxide is tenacious and it can be difficult to get through to arrive at an accurate and repeatable measurement.

Wed, Jul 31, 2019 @ 02:14 PM Omni Team Aluminum Trace PCB - Superconductive PCB

Read More »

Development was driven by D-Wave’s need for low temperature PCBs which could provide mono-metal superconductive connection to their unique quantum processors (QPUs).

The PCBs would operate at cryogenic low-temperature, be solderable and be suitable for wire-bonding. The PCB would also withstand multiple temperature cycling from below 500 Millikelvin to 20°C.

Mon, Jul 01, 2019 @ 02:40 PM Omni Team Aluminum Trace PCB - Superconductive PCB

Read More »

D-Wave Systems Inc. turned to Omni Circuit Boards to help them build the first "Superconductive Aluminum-Trace Printed Circuit Boards" that serves as interface with their QPUs (quantum processing units)

Mon, Apr 01, 2019 @ 11:24 AM Omni Team Aluminum Trace PCB - Superconductive PCB

Read More »

While some customers are investigating frontiers in MEMS (Microelectromechanical systems), others are delving into the inherent superconductive properties at milliKelvin temperatures, while still others are exploiting the radiation response characteristics of aluminum. For the R&D personnel at Omni Circuit Boards, the requests have presented some interesting challenges.

Fri, Mar 29, 2019 @ 01:40 PM Omni Team Aluminum Trace PCB - Superconductive PCB

Read More »

Vancouver, BC, January 7, 2015 University of British Columbia Department of Materials Engineering and Omni Circuit Boards have been awarded an Engage Grant (EG) through the National Sciences and Engineering Research Council of Canada.

Sat, Feb 21, 2015 @ 03:22 PM Omni Team Aluminum Trace PCB - Superconductive PCB

Read More »

Vancouver, BC, January 13, 2015—

Omni Circuit Boards Ltd.

announced today the signing of a research and development agreement with D-Wave Systems Inc., the first commercial quantum computing company, in support of the further advanc ement of aluminum trace printed circuit boards (Al-PCB) for quantum computing applications.Tue, Jan 13, 2015 @ 01:25 PM Omni Team Aluminum Trace PCB - Superconductive PCB

Read More »