A circuit trace is a conducting track on a printed circuit board that connects components electrically and allows electric current to flow with little resistance.

A circuit trace is a conducting track on a printed circuit board that connects components electrically and allows electric current to flow with little resistance.

While this small resistance is inconsequential for most applications, there are applications where the heat dissipated due to this small resistance is a big problem.

Much like how normal conducting trace allows current to flow, they also allow heat to flow from higher temperature areas to areas of lower temperature.

A superconducting trace connects components electrically and allows electric current to flow, but does so while providing zero electrical resistance.

Superconducting traces allow current to flow with zero dissipation.

While superconductivity is not encountered in metals at "everyday" temperatures, some metals transition from regular conductors to superconductors when cooled to low enough temperature.

Where are Superconducting Circuit Traces currently being used?

PCBs with superconducting circuit traces are already enabling the study of low-temperature physics, quantum computers, space exploration in radio telescopes and balloon-borne telescopes and rapid single flux quantum digital electronics technologies. They could provide benefits in many more applications.

Primary design consideration for Superconducting PCBs

Before incorporating superconducting traces into a PCB design, one must consider that superconductors conduct electrical current easily, but they are very poor conductors of heat. This is why we believe the ideal superconducting trace is a bimetal one.

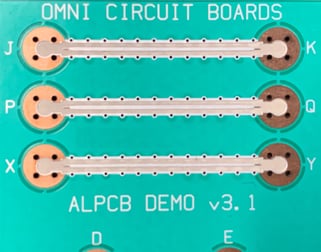

Omni's standard superconducting traces consist of aluminum (a conducting metal that superconducts at cryogenic temperatures) over copper (a conducting metal at normal and cryogenic temperatures that carries heat away).

We call these "Aluminum-Trace PCBs."

Benefits of Superconducting Circuit Traces

Current flowing through copper traces always generates some amount of heat, no matter how small the current is. By the same mechanism that dissipates heat, the current generates electrical noise. If you have tiny signals that you are trying to detect, like from a distant star, you need the lowest noise possible. Superconducting traces eliminate thermal noise.

Are Superconducting Circuit Traces practical for your application?

To maintain superconductivity, you need to accommodate certain restrictions:

- The superconducting circuit traces must be made of certain metals, like pure tin, lead-tin solder or aluminum, among others.

- Every part of the superconducting circuit trace has to be maintained below a certain temperature threshold to superconduct. Different metals and alloys have different temperature thresholds.

- You cannot exceed a certain current, which depends on the metal, size (wire gauge) of the trace, the temperature, and other parameters.

- Your application cannot exceed a specific ambient magnetic field to maintain superconductivity.

If your application can meet these conditions, you can benefit from zero generated heat facilitated by the use of superconductive aluminum traces, or "Aluminum-Trace PCBs."

Omni can help you navigate these restrictions. You can start by giving us a call or sending an e-mail to sales(at)omnicircuitboards.com