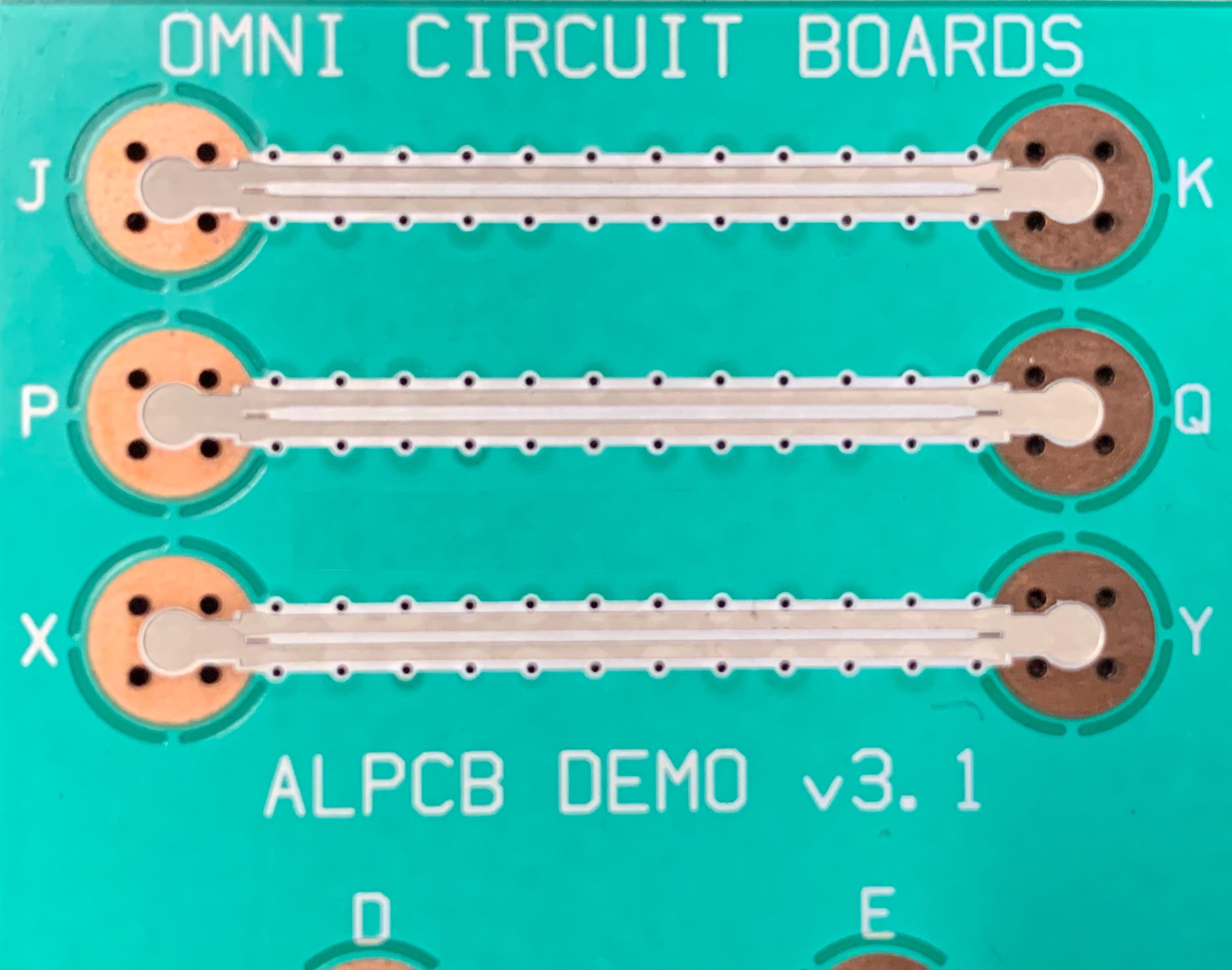

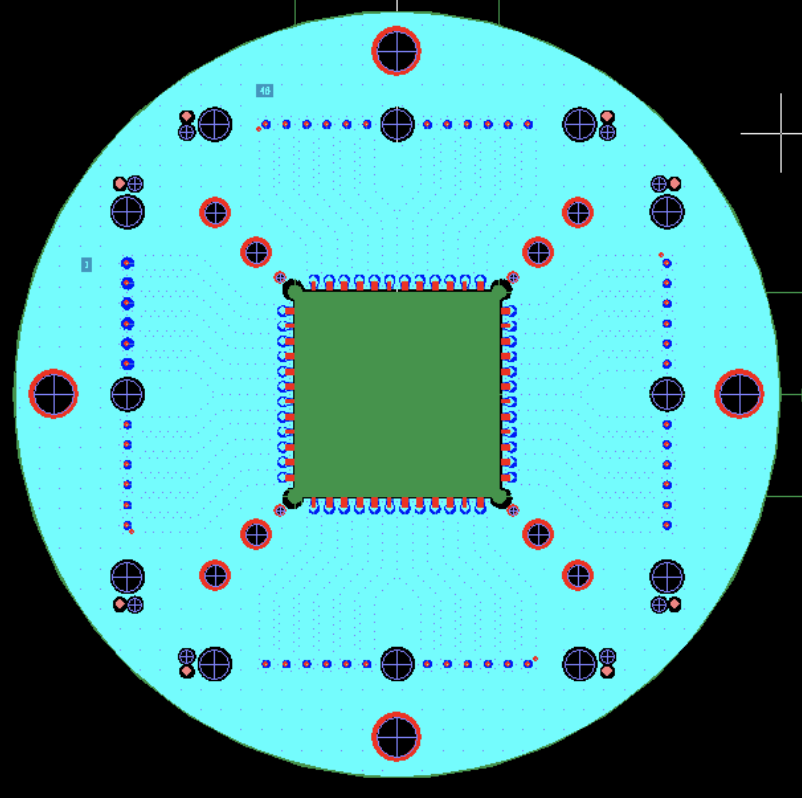

A circuit trace is a conducting track on a printed circuit board that connects components electrically and allows electric current to flow with little resistance.

While this small resistance is inconsequential for most applications, there are applications where the heat dissipated due to this small resistance is a big problem.

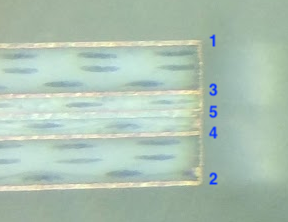

Much like how normal conducting trace allows current to flow, they also allow heat to flow from higher temperature areas to areas of lower temperature.