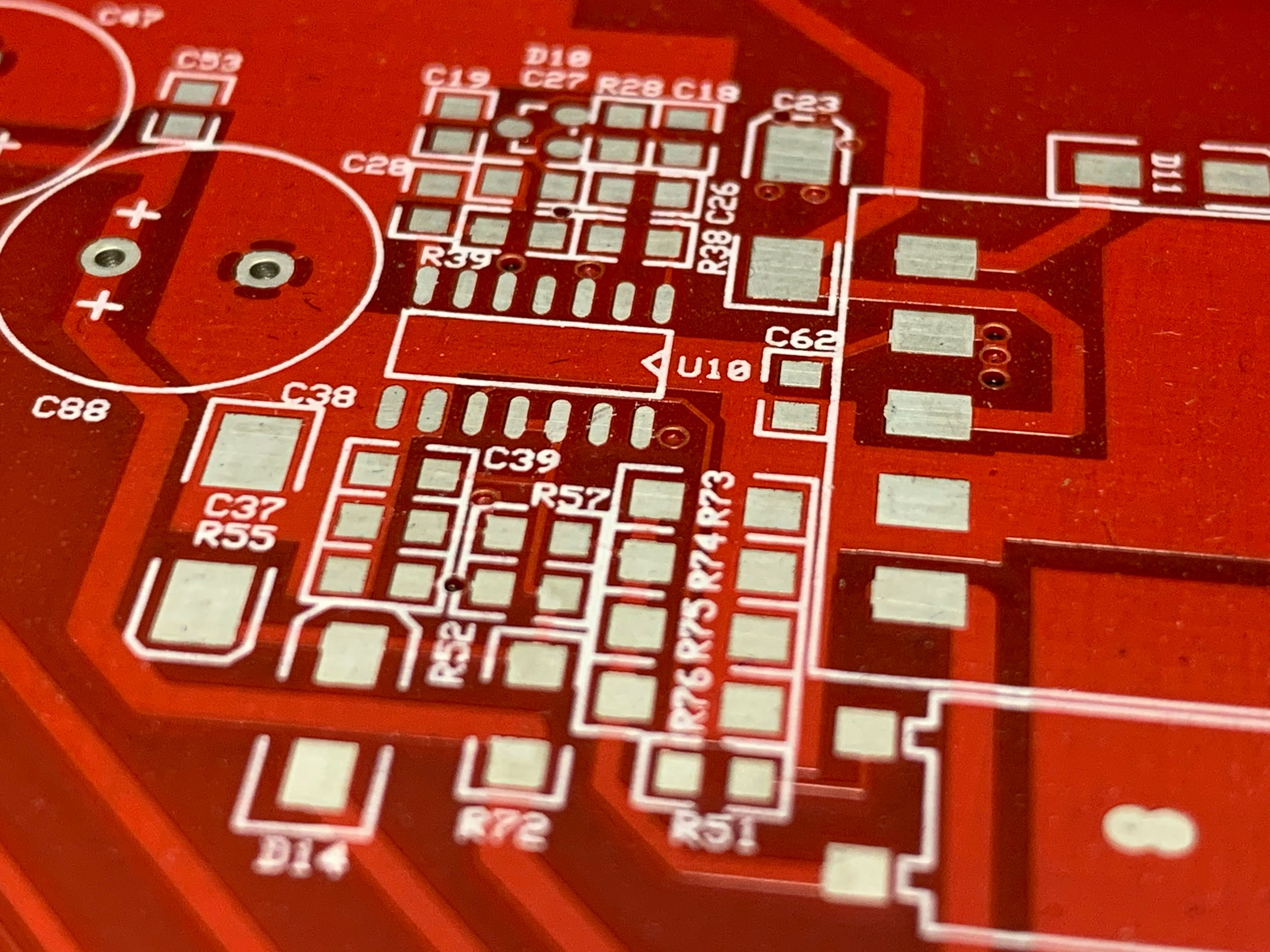

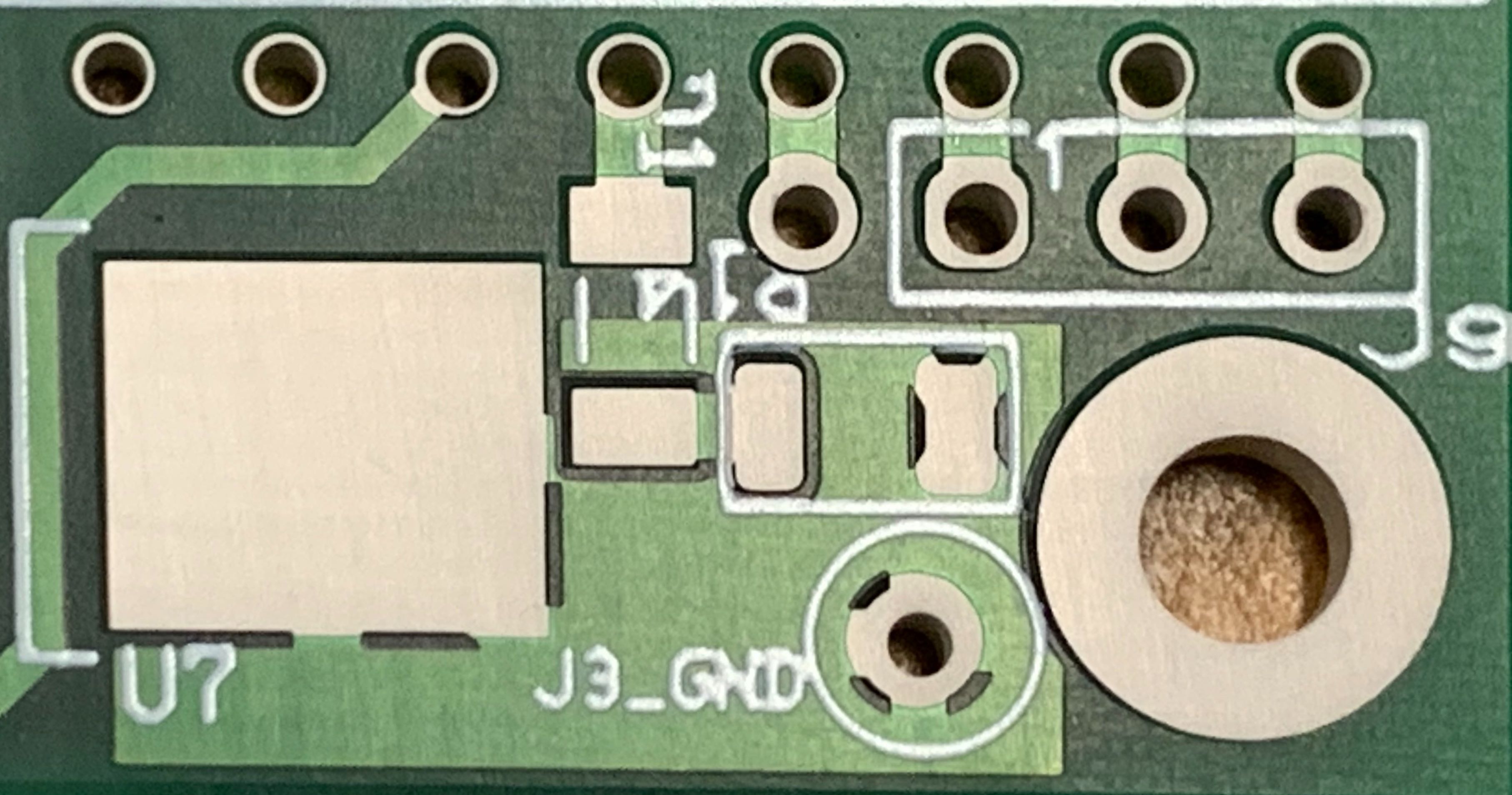

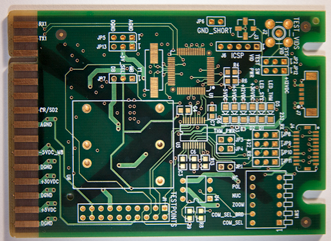

As you might expect, no two applications for aluminum trace circuit boards are the same and most often they are not even similar.

While some customers are investigating frontiers in MEMS (Microelectromechanical systems), others are delving into the inherent superconductive properties at milliKelvin temperatures, while still others are exploiting the radiation response characteristics of aluminum. For the R&D personnel at Omni Circuit Boards, the requests have presented some interesting challenges.