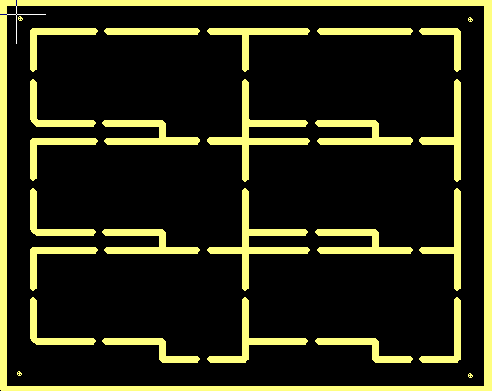

Avoid these four circuit board design mistakes:

1. Stipulating a "minus" tolerance on small micro via holes

2. Having Non-functional pads on inner layers

3. Not defining nor considering edge tolerances

4. Stipulating wrong copper thicknesses

1. Stipulating a "minus" tolerance on small micro via holes

2. Having Non-functional pads on inner layers

3. Not defining nor considering edge tolerances

4. Stipulating wrong copper thicknesses

Fri, May 31, 2019 @ 03:56 PM Omni Team Printed Circuit Board Design

Read More »%20microwave%20laminate.png)

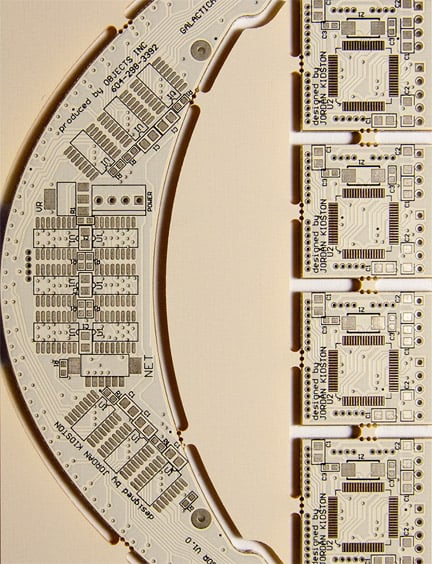

When beginning work with a new material, you try to do as much research and get as much advice as possible.

You download the manufacturers documentation and talk with the manufacturers representatives, drill/router bit manufacturers and other PCB manufacturers who have worked on the material in the past.

After compiling all this information, a manufacturing process is developed which fits both the material and your own facility.

Wed, May 01, 2019 @ 12:31 PM Omni Team Printed Circuit Board Design

Read More »

PCB Manufacturer = The company that manufactures blank PCBs for you, Omni Circuit Boards Ltd is a "PCB Manufacturer"

PCBA Manufacturer = The company that manufactures an assembled or populated PCB for you, also known as CMs or contract manufacturers.

Mon, Apr 29, 2019 @ 04:21 PM Omni Team Printed Circuit Board Design

Read More »