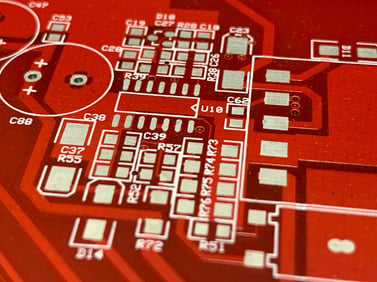

If you work with printed circuit boards or the PCBA industry, then you have probably heard of Immersion White Tin, but may have questions about how it actually works and whether it's a process that you should care about.

Given that we are leaders in Immersion White Tin PCB fabrication here at Omni, it goes without saying that we are heavily in favor of its use.

To understand why, you first have to understand the reason behind our preference for white tin in the first place.

Traditionally, printed circuit boards have been finished with a coating of material to protect them from oxidation and allow for components to be soldered onto them in a reliable consistent way, this is usually specified to as "PCB Finish" and requires the use of Lead (HASL) and vast amounts of water during processing (All other PCB finish types).

White Tin does not involve the use of Lead and it utilizes the least amount of water during the manufacturing process compared to all other PCB Finish types, plus it is cheaper than other metals, i.e. "gold" used on an ENIG PCB Finish.

By choosing immersion white tin as a pcb finish, we are able to achieve the same effect of other finishes, but with lower impact to health and environment.

In other words, immersion white tin is a better way to meet the goal of environmentally friendly printed circuit board manufacturing.

With that basic explanation of immersion white tin and PCB boards out of the way, let's look at the two things you really need to know:

1. Immersion white tin is environmentally friendly.

By taking the toxins, harmful metals, and byproducts out of the PCB manufacturing process, what we are left with isn't just less damaging, but is also more sustainable than the alternatives. Regardless of how you look at it, our printed circuit boards are a responsible, cutting-edge way to meet design and manufacturing needs. And for those looking for the most environmentally friendly printed circuit boards, it’s hard to find a reliable solution with a lower impact than our RoHS compliant Immersion White Tin finish.

2. Immersion white tin lets you achieve a balance between an environmentally friendly pcb and minimizing production and design tradeoffs.

As great as this technology is for reducing the environmental impact of printed circuit production, it's just as favorable for your bottom line. Unlike some systems, which increase your costs, using immersion white tin doesn't mean paying more for printed circuit board fabrication (ENIG, Hard Gold) or accepting a less reliable product (OSP).

In reality, though, it isn’t customer demand that led us to be a leader in the industry, but the fact that we think it's absolutely the right thing to do and the responsible way to work as a PCB manufacturer.

By working with this technology we can feel good about the company we operate.