Mention Immersion White Tin around sales people from PCB shops and Tin Whiskers will inevitably be part of the topic.

They may not feel comfortable down mouthing the competition in public but a process? Well that’s fair game. What the salespeople don’t know or won’t tell you is the Immersion Tin used as a finish for circuit boards completely dissolves in the solder used in the circuit board assembly process.

Considerable research is out there to show whiskers which do occur are mainly from the tinned leads of installed components or from lead free solder. Another great way to ensure you won’t have any issues is to have your PCB manufactured at a knowledgeable shop with in-control finishing processes.Besides sustainability, Immersion Tin is also able to offer:

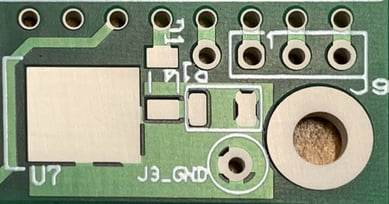

- Greater flexibility with fine component pitch requirements

- Less press fit restrictions particularly on boards with thicker substrates

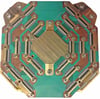

- A uniform, flat and dense solderable surface that is desirable for surface mount components

- Processes which require lower Power and Water consumption to produce, which you may not appreciate when you have your boards in-hand, but we do.

As more and more manufacturers embrace lean manufacturing concepts, the need for storing bare boards for multiple years also declines. At Omni, we are seeing more and more examples of multiple reorders of lesser quantities and shorter intervals as manufacturers align supply with demand. This in turn ensures rapid turnover of material and lessens the chance of shelf damage which will occur eventually to any PCB finish.

How do we know we are backing the right process?

We regularly supply contract manufacturers directly and in many cases Omni and our Immersion White Tin finish is the preferred supplier. Due to the properties of Immersion White Tin not found in other finishes, we also have new product development customers who have let us know if we drop Immersion White Tin they will find someone who does offer it.

So how did Immersion White Tin turn into the Red Headed Stepchild of PCB finishes?

In our humble opinion, part of the reason is a lack of sustained marketing and information campaigns from the suppliers. The market leader for Immersion Tin Chemicals, Enthone in particular, has superior products and yet their sustained marketing presence is severely lacking.

According to some sources, Immersion White Tin and Organic metals will become the unequivocal finishing process as worldwide environmental legislation will ban its contemporaries.

In the meantime, Omni Circuit Boards will extol the virtues of Immersion White Tin but should you send us an order with ENIG or HASL, we’ll still execute on it.