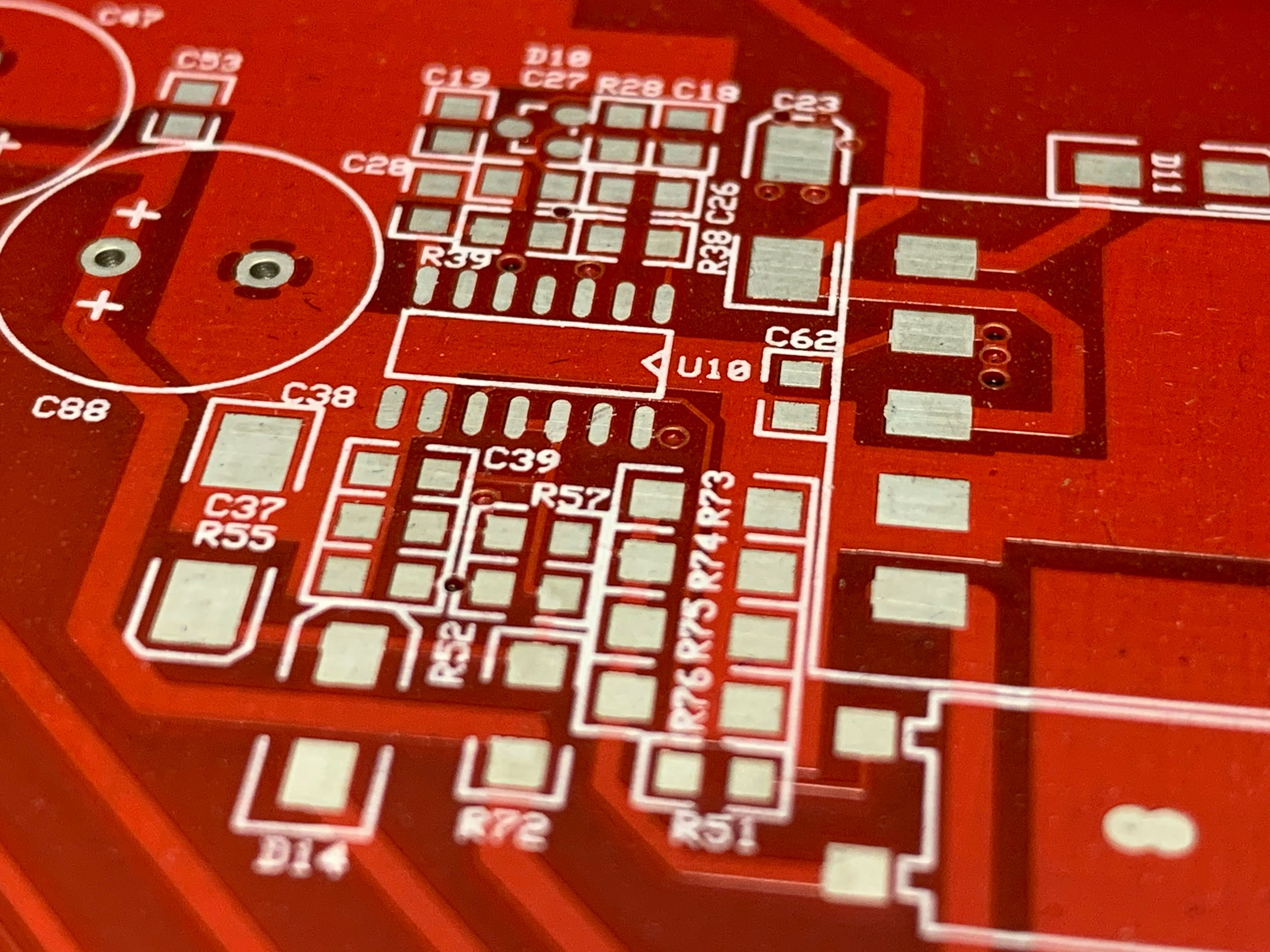

One of the more artistic processes in a PCB manufacturing facility is the application of Silkscreen known in the old days as Ident layers.

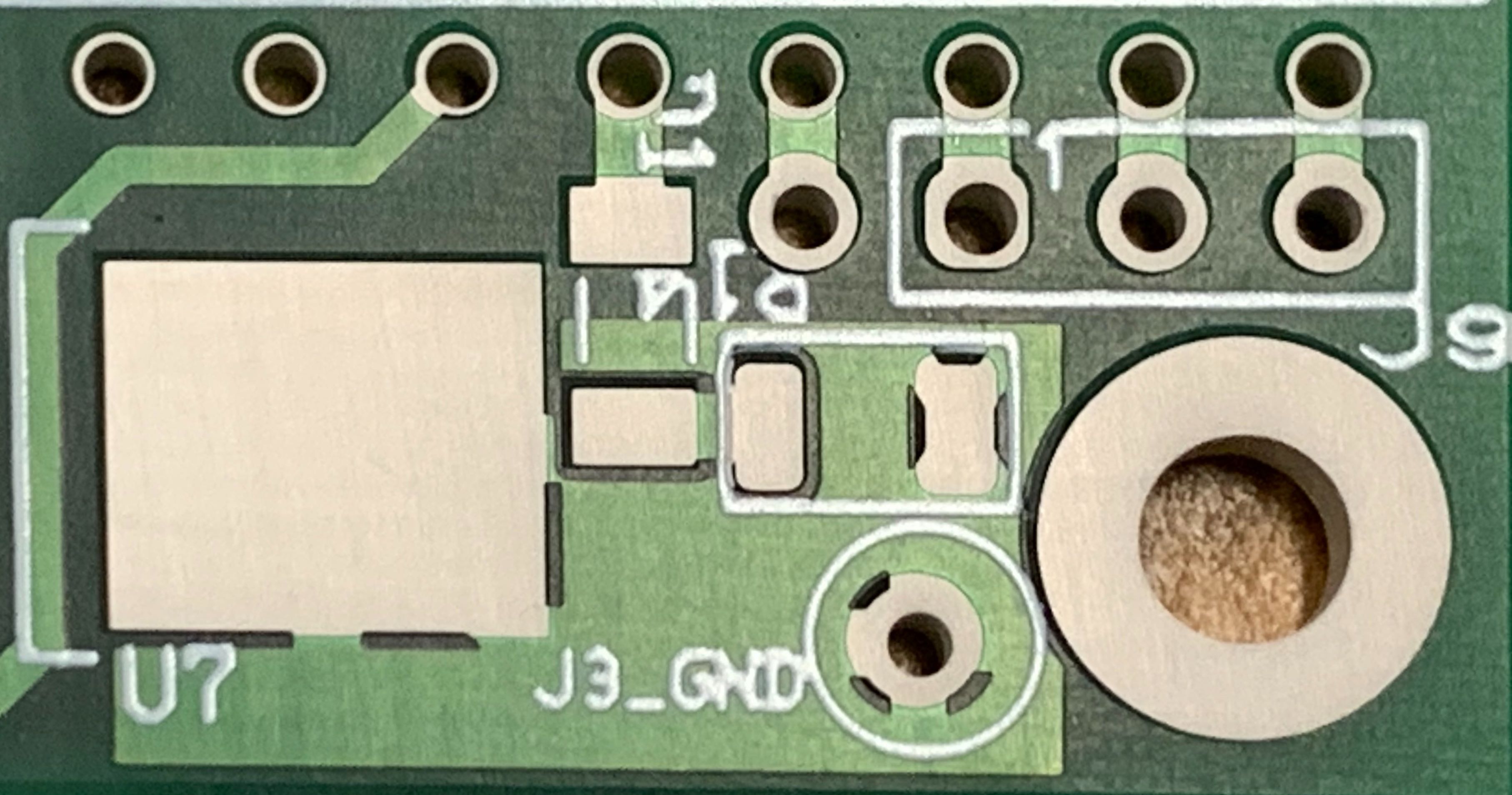

Silkscreen is usually white and human readable letters, normally used to identify components, test points, PCB and PCBA part numbers, warning symbols, company logos, date codes and manufacturer marks.

Silk-screening requires specially formulated inks. The standard colour is white, but you can also select red, blue, black, yellow, etc.